Dana Making Machine Manufacturer

Dana Making Machine Manufacturer

Introduction

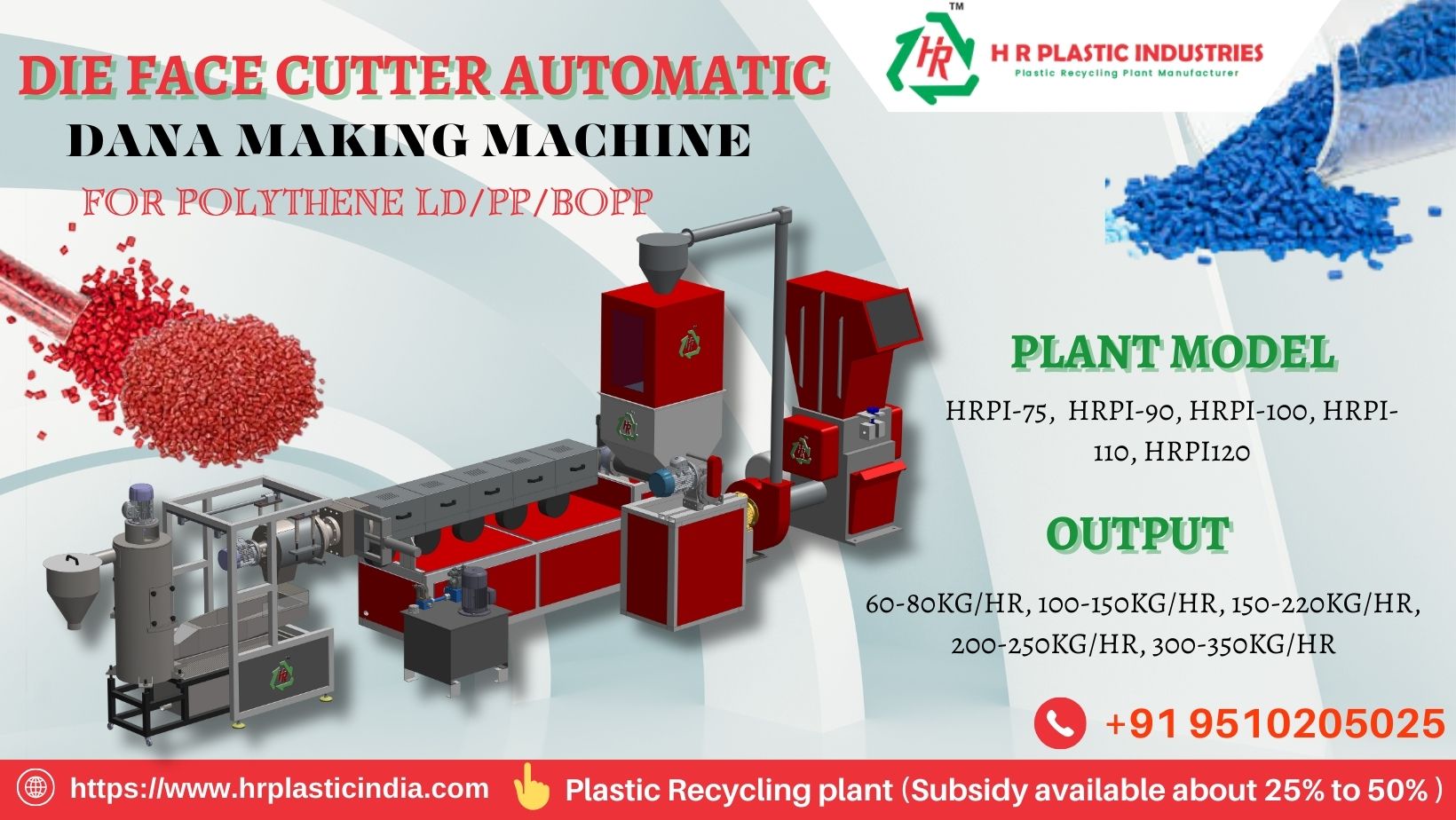

As a trusted Dana Making Machine Manufacturer, we specialize in designing and manufacturing high-performance machinery for plastic granule (dana) production. These machines are integral to plastic recycling and extrusion industries, transforming plastic waste or raw materials into reusable granules used in molding, extrusion, and compounding processes. Our machines deliver high output, energy efficiency, and consistent quality, meeting the demands of modern plastic processors.

Application Area

Dana making machines are widely used in:

-

Polymer Processing Units

-

Plastic Compounding Facilities

-

Injection and Blow Molding Industries

-

Plastic Film and Sheet Manufacturers

-

PVC, PET, HDPE, LDPE, and PP Pelletizing Plants

Uses Material

Our dana making machines can process various types of plastic materials, including:

| Plastic Type | Examples |

|---|---|

| Polyethylene | LDPE, LLDPE, HDPE |

| Polypropylene | PP, Co-PP |

| Polyvinyl Chloride | Soft and Rigid PVC |

| Polyethylene Terephthalate | PET Bottles and Straps |

| Engineering Plastics | ABS, Nylon (PA), PC |

| Recycled Plastics | Post-consumer & post-industrial waste |

| Filled Polymers | Calcium or Talc filled materials |

-

Screw-barrel made of nitrided or bimetallic steel

-

Automatic temperature control system

-

Heavy-duty pelletizer (die face cutter or strand pelletizer)

-

Integrated water ring or air cooling systems

-

Hopper loader and dust-free feeding system

-

Easy to operate PLC or manual control panel

Benefits

-

Consistent Granule Size – Ensures superior downstream processing

-

Energy Efficient – Lower operational costs with optimized design

-

High Output Capacity – Suitable for mass production

-

Durable Build – Long service life even under heavy use

-

Easy Maintenance – Modular design simplifies cleaning and repairs

-

Versatile – Handles a wide range of plastic types and blends

-

Reduced Waste – Enhances material utilization and sustainability

Why Choose Us

-

Proven Manufacturer – Years of experience in plastic machinery

-

Custom Solutions – Machines tailored to your capacity and material

-

Global Standards – CE and ISO-certified production lines

-

Technical Support – Onsite installation, training, and after-sales service

-

Spare Parts Availability – Readily available parts for fast maintenance

-

Competitive Pricing – Quality and performance at the best value

-

Client Satisfaction – Trusted by over 500+ industrial clients globally

Conclusion

As a leading Dana Making Machine Manufacturer, we provide reliable, cost-effective, and high-performance solutions for the plastic recycling and processing industry. Whether you're building a new plant or upgrading your production line, our machines offer the quality, consistency, and support you need to scale efficiently.

FAQ

Q1: What is the production capacity of your dana machines?

A: We offer models ranging from 50 kg/hr to over 1000 kg/hr, depending on your requirements.

Q2: Can I use mixed plastic waste in the machine?

A: Yes, with pre-sorting and washing, mixed plastics can be processed efficiently.

Q3: Do you offer water ring and die face cutter options?

A: Absolutely. Both cooling options are available depending on the material and output preference.

Q4: How much power does a typical machine consume?

A: Power ranges from 15 HP to 100+ HP depending on the model. All machines are energy-optimized.

Q5: Can you customize the machine for color masterbatch or filler compounds?

A: Yes, we offer special screw designs and mixing features for such applications.

Tag List

Filter Using Tags