Plastic Granulating Machine Manufacturer

Plastic Granulating Machine Manufacturer

Company Description

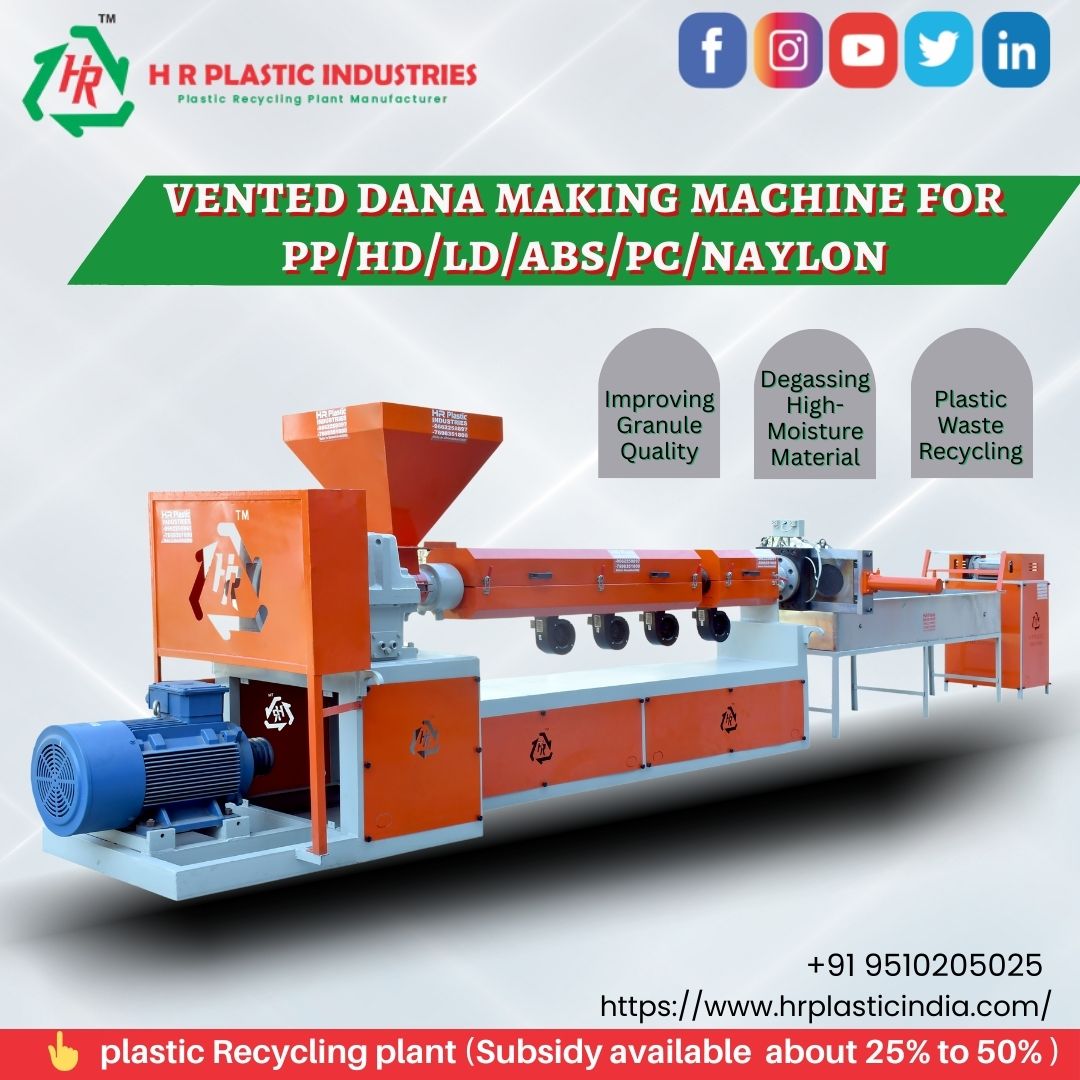

As a leading manufacturer of plastic granulating machines, we specialize in designing and producing high-performance equipment for the recycling industry. Our machines are engineered to transform plastic waste—such as film, bottles, pipes, and injection-molded parts—into uniform, high-quality granules that can be reused for manufacturing. With decades of industry expertise, we deliver durable, energy-efficient, and low-maintenance solutions suitable for various plastic processing needs.

How It Works

A plastic granulating machine works through a multi-stage process:

-

Feeding

Plastic waste is loaded into the machine via a conveyor or manual feed hopper. -

Cutting/Shredding

Inside the cutting chamber, high-speed rotating and stationary blades shear the material into smaller flakes. -

Granulating

The shredded material passes through a screen mesh that ensures uniform granule size. -

Cooling

Optional water or air-cooling systems prevent heat damage during granulation. -

Discharge & Collection

Finished granules are discharged and collected for packaging or immediate reuse.

Benefits

-

Cost Saving: Reduces the need for virgin raw plastic by reusing recycled material.

-

Environmentally Friendly: Promotes plastic recycling and reduces landfill waste.

-

Efficient: Capable of processing large volumes of material continuously.

-

Customizable Output: Screen sizes and blade settings can be adjusted for different granule sizes.

-

Low Maintenance: Designed for easy blade access, cleaning, and part replacement.

Features Table

| Feature | Details |

|---|---|

| Blade Material | High-carbon steel or SKD-11/D2 for durability and cutting precision |

| Cutting System | V-type or Claw-type rotor for consistent granulation |

| Screen Aperture | Customizable mesh sizes (from 10mm to 100mm) |

| Motor Power | Available from 15 kW to 110 kW depending on the model |

| Noise Reduction | Enclosed body design with sound insulation |

| Cooling Options | Air-cooled or water-cooled configurations |

| Safety Controls | Emergency stop, interlocks, and motor overload protection |

| Construction Material | Heavy-duty steel frame with anti-corrosion coating |

Our granulating machines are engineered with industrial-grade motors, precision-engineered cutting chambers, and optimized airflow or water-cooling systems. Each machine is designed for high torque and stable performance, even when processing tough plastic materials. The inclusion of high-speed rotors ensures fast output without compromising on granule uniformity. Technological innovations such as automatic overload protection, PLC control systems, and real-time temperature monitoring improve safety and performance consistency.

Why Choose Us

-

Industry Expertise: Over 20 years of experience in plastic recycling equipment manufacturing.

-

Custom Solutions: Machines tailored to client specifications—material type, output size, and capacity.

-

Quality Assurance: Strict quality control from fabrication to final testing ensures long-lasting performance.

-

After-Sales Support: Full technical support, spare parts availability, and installation guidance.

-

Sustainability Focused: We support circular economy goals by enabling efficient plastic recycling.

-

Global Reach: Machines operating successfully in over 30 countries with positive client feedback.

Technical Data (Example Models)

| Model | Capacity (kg/h) | Motor Power (kW) | Rotor Diameter (mm) | Blade Quantity | Screen Size (mm) |

|---|---|---|---|---|---|

| PG-400 | 300 – 500 | 22 | 400 | 3 Fixed / 6 Rotary | 10 – 20 |

| PG-600 | 600 – 1000 | 37 | 600 | 4 Fixed / 12 Rotary | 10 – 20 |

| PG-800 | 1000 – 1500 | 55 | 800 | 4 Fixed / 18 Rotary | 10 – 20 |

| PG-1000 | 1500 – 2000 | 75 | 1000 | 6 Fixed / 24 Rotary | 10 – 20 |

Q1: What types of plastic can your machine process?

A: Our machines can granulate various plastic types including PET, HDPE, LDPE, PP, PVC, ABS, PS, and engineering plastics.Q2: Can your machines process both rigid and soft plastics?

A: Yes, models are available for both hard plastics (like bottles, containers) and soft plastics (films, bags).Q3: How often do the blades need replacement or sharpening?

A: Blade life varies with material type but typically lasts 150–300 hours before sharpening. Our design allows easy removal and sharpening.Q4: How do I choose the right model for my needs?

A: It depends on the type of plastic, required output per hour, and desired granule size. We offer consultations to help select the best model.Q5: What power supply is needed?

A: Most models require a 3-phase industrial power connection (380V or as per local standards).Q6: Is operator training provided?

A: Yes, we offer remote or on-site training during installation and commissioning.Q7: What safety features are included?

A: Safety interlocks, emergency stop buttons, overload protection, and rotor guards are standard in all models.Conclusion

Investing in a plastic granulating machine from a trusted manufacturer ensures high performance, efficient recycling, and long-term reliability. Our machines are built to meet the demands of modern recycling facilities while supporting sustainable and cost-effective production practices.

Company Description

As a leading manufacturer of plastic granulating machines, we specialize in designing and producing high-performance equipment for the recycling industry. Our machines are engineered to transform plastic waste—such as film, bottles, pipes, and injection-molded parts—into uniform, high-quality granules that can be reused for manufacturing. With decades of industry expertise, we deliver durable, energy-efficient, and low-maintenance solutions suitable for various plastic processing needs.

How It Works

A plastic granulating machine works through a multi-stage process:

-

Feeding

Plastic waste is loaded into the machine via a conveyor or manual feed hopper. -

Cutting/Shredding

Inside the cutting chamber, high-speed rotating and stationary blades shear the material into smaller flakes. -

Granulating

The shredded material passes through a screen mesh that ensures uniform granule size. -

Cooling

Optional water or air-cooling systems prevent heat damage during granulation. -

Discharge & Collection

Finished granules are discharged and collected for packaging or immediate reuse.

Benefits

-

Cost Saving: Reduces the need for virgin raw plastic by reusing recycled material.

-

Environmentally Friendly: Promotes plastic recycling and reduces landfill waste.

-

Efficient: Capable of processing large volumes of material continuously.

-

Customizable Output: Screen sizes and blade settings can be adjusted for different granule sizes.

-

Low Maintenance: Designed for easy blade access, cleaning, and part replacement.

Features Table

| Feature | Details |

|---|---|

| Blade Material | High-carbon steel or SKD-11/D2 for durability and cutting precision |

| Cutting System | V-type or Claw-type rotor for consistent granulation |

| Screen Aperture | Customizable mesh sizes (from 10mm to 100mm) |

| Motor Power | Available from 15 kW to 110 kW depending on the model |

| Noise Reduction | Enclosed body design with sound insulation |

| Cooling Options | Air-cooled or water-cooled configurations |

| Safety Controls | Emergency stop, interlocks, and motor overload protection |

| Construction Material | Heavy-duty steel frame with anti-corrosion coating |

Our granulating machines are engineered with industrial-grade motors, precision-engineered cutting chambers, and optimized airflow or water-cooling systems. Each machine is designed for high torque and stable performance, even when processing tough plastic materials. The inclusion of high-speed rotors ensures fast output without compromising on granule uniformity. Technological innovations such as automatic overload protection, PLC control systems, and real-time temperature monitoring improve safety and performance consistency.

Why Choose Us

-

Industry Expertise: Over 20 years of experience in plastic recycling equipment manufacturing.

-

Custom Solutions: Machines tailored to client specifications—material type, output size, and capacity.

-

Quality Assurance: Strict quality control from fabrication to final testing ensures long-lasting performance.

-

After-Sales Support: Full technical support, spare parts availability, and installation guidance.

-

Sustainability Focused: We support circular economy goals by enabling efficient plastic recycling.

-

Global Reach: Machines operating successfully in over 30 countries with positive client feedback.

Technical Data (Example Models)

| Model | Capacity (kg/h) | Motor Power (kW) | Rotor Diameter (mm) | Blade Quantity | Screen Size (mm) |

|---|---|---|---|---|---|

| PG-400 | 300 – 500 | 22 | 400 | 3 Fixed / 6 Rotary | 10 – 20 |

| PG-600 | 600 – 1000 | 37 | 600 | 4 Fixed / 12 Rotary | 10 – 20 |

| PG-800 | 1000 – 1500 | 55 | 800 | 4 Fixed / 18 Rotary | 10 – 20 |

| PG-1000 | 1500 – 2000 | 75 | 1000 | 6 Fixed / 24 Rotary | 10 – 20 |

Q1: What types of plastic can your machine process?

A: Our machines can granulate various plastic types including PET, HDPE, LDPE, PP, PVC, ABS, PS, and engineering plastics.Q2: Can your machines process both rigid and soft plastics?

A: Yes, models are available for both hard plastics (like bottles, containers) and soft plastics (films, bags).Q3: How often do the blades need replacement or sharpening?

A: Blade life varies with material type but typically lasts 150–300 hours before sharpening. Our design allows easy removal and sharpening.Q4: How do I choose the right model for my needs?

A: It depends on the type of plastic, required output per hour, and desired granule size. We offer consultations to help select the best model.Q5: What power supply is needed?

A: Most models require a 3-phase industrial power connection (380V or as per local standards).Q6: Is operator training provided?

A: Yes, we offer remote or on-site training during installation and commissioning.Q7: What safety features are included?

A: Safety interlocks, emergency stop buttons, overload protection, and rotor guards are standard in all models.Conclusion

Investing in a plastic granulating machine from a trusted manufacturer ensures high performance, efficient recycling, and long-term reliability. Our machines are built to meet the demands of modern recycling facilities while supporting sustainable and cost-effective production practices.

Filter Using Tags